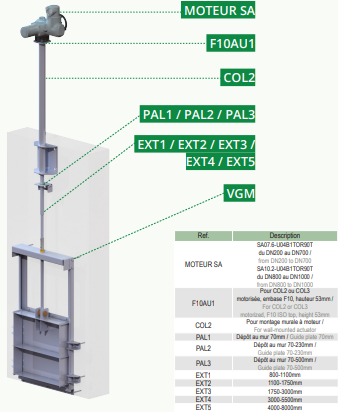

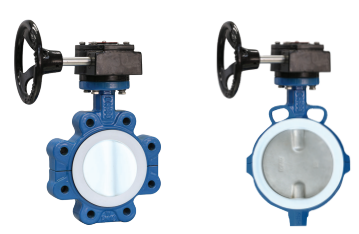

TECFLY - VPI

• DN 40 up to 300

• Body : cast iron EN-GJS-400 Disc : ductile iron EN-GJS-400 + Nickel Sleeve : HEAT EPDM

• Working pressure : 16 bar Connection : wafer type or lug type

TECFLY - VPG

• DN 40 up to 300

• Body : cast iron EN-GJS-400 Disc : ductile iron EN-GJS-400 + Nickel Sleeve : HEAT EPDM

• Working pressure : 16 bar Connection : wafer type or lug type

TECFLON

• DN 40 up to 300

• Ductile iron GGG50 body

• Stainless steel disc PTFE lined

•PTFE sleeve with FPM insert

• COATING Painting: oven backed epoxy powder coating, 150 μ

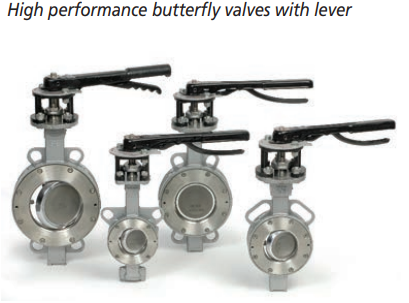

TECSUP

• DN 50 up to 1200

• Double or triple eccentric type butterfly valves for high temperatures and high pressures. Lugged, flanged or welded connections

TECSUP

• DN 50 up to 1200

• Body: . steel ASTM A 216 Gr. WCB, . stainless steel ASTM A 351 Gr. CF8 / CF8M / CN7M / 904 L (Uranus B6®).

- Disc: stainless steel ASTM A 351 Gr. CF8 / CF8M / CN7M / WCB / 904 L (Uranus B6®).

- Seat(1): PTFE (standard up to 200°C) / ASTM A 276 type 316 / Inconel.

- Stem: stainless steel 17-4 PH, ASTM A 276 type 410/304/316 and A-20.

- Stem bearing: PTFE / ASTM A 351 Gr. CD4MCu / Ni-Resist.

- Handle unit(2): carbon steel.

- Gear unit(3): gear in carbon steel EN8 / bolts in EN8 - EN19.

- Surface protection for cast carbon steel valves : . prime coat: chlorine free with modified alkyd resin unobjectionable in physiological and toxicological respects, . additional external coating: heat resistant silver streak aluminium paint

TECLARGE / TECLARGE FL

■ APPLICATION

General use: water, sea water, sludge, hydrocarbons, etc.

■ MODELS

Standard TECLARGE: between flange wafer PN 10 (PN 16 and ASA 150 on request).

TECLARGE FL: double flange PN 10 (PN 16 and ASA 150 on request).

■ GENERAL CHARACTERISTICS

- Design in accordance with NF EN 593. - Tightness in both ways. NFEN 12266-1, NFEN 12266-2 - ISO 5208 - DIN 3230.

- Face to face in accordance with: ISO 5752 series 20, NF EN 558-1 serie 20.

- Two kinds of sleeve:

• DN 350 and 400: body in dovetail shape ensures a perfect assembling (for high vacuum we can stick it) ;

• DN 450 to 1200: sleeve internally reinforced in aluminium giving a low torque.

- Stem: half stem high and low or crossing stem depending on the diameter.

- Coupling stem on disc assembled by conical pin.

- Self lubricant bearing in copper alloy.

- Supplementary tightness on stem by o'rings.

■ CONSTRUCTION MATERIALS

- Body: cast iron or ductile iron.

- Disc: ductile iron.

- Sleeve: heat EPDM. Other possibilities on request.

■ WORKING CONDITIONS

- Maximum working pressure: 10 bar ( 16 bar on request).

- Maximum working temperature: 130°C (sleeve: heat EPDM).

- Manufacture according to the requirements of the European

directive 97/23/CE «Equipments under pressure» : category III

modulate H.

- Test procedures are established according to NFEN 12266-1, NF EN 12266-2 - DIN 3230 ISO 5208.

■ CONNECTION

- TECLARGE: between flanges ISO PN 10 according to EN 1092-2 (PN 16 and ASA 150 on request). 2 lugs up & down with smooth holes or threaded depending on diameter.

- TECLARGE FL: double flange ISO PN 10 according to EN 1092-2 (PN 16 et ASA 150 on request). Assembling by string or screw.

■ HANDLING POSSIBILITIES

Mounting plate in accordance with ISO 5211 for easy assembling of following operating systems:

- manual gear box with position indicator,

- single or double acting pneumatic actuator, - electric actuator 48, 230/400 V, single or three phases, 50 or 60 Hz

.

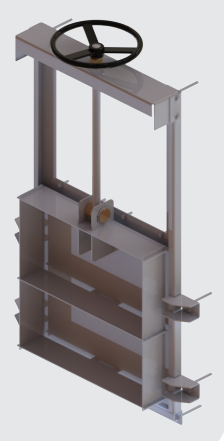

TECOFI Provide of Penstock Range; Wall Mounted, Frame / Channel Mounted, Manual Actuation

TECOFI Provide of Penstock Range; Wall Mounted, Frame / Channel Mounted, Actuated Electric